Glickenhaus transitions race-winning business into opportunity to help healthcare providers

When the Baja Boot took the finish line at the 2019 Baja 1000, I knew then its team was charmed. SCORE, the sanctioning body for one of the toughest races on the planet, had capped the finishing time for all vehicles at 34 hours. The Glickenhaus team, with noted off-road racer Darren Skilton at the wheel, commandeered this renowned 4WD model through the gate at 33 hours, 59 minutes, and 13.09 seconds-with less than 47 seconds to spare! The Boot was the second-to-last vehicle to finish and took more than twice the time of the overall winner, for the 52nd annual event that had suffered a day’s delay to the start, due to flooding. When the race began, there were many mud-soaked sections of the already-rough-and rugged course; out of 264 starters only 145 finished—this 54.92 percentage was considered “good”, considering the added difficulties along the track. The Boot finished and took home a class win, despite trials along the way.

The original Baja Boot was purchased by noted Ferrari collector and SCG proprietor James Glickenhaus and used as the platform to work the mojo with the current-gen Boot. Its 350 cubic-inch GM small-block was upgraded to a 6.2-liter, 460-horsepower LT1 V-8 derived from the Chevy Camaro SS that is mated to a 4L80E four-speed automatic. Sitting on a wheelbase of 116 inches, with a width of 84 inches and a height of 6ft. 7 inches, it runs on 4WD, four-wheel independent suspension with 19-inches of travel; Fox coil over 3-in. internal bypass shocks and has 40-in. tires; Method 17-in. Race Wheels Mounted with 37-in. BFGoodrich All-Terrain T/A K02 tires (Optional 40s); Wilwood Dynapro Calipers w/ 12-in.rotor brakes; and has a range of 400 miles highway and 200/300 miles off-road. It is available with a soft top with optional removable hardtop.

As I watched history being made in Ensenada, Mexico, I had no idea that I would see another impressive story unfold during the early stages of the coronavirus’s ravage of the U.S. about the noted father and son duo that developed the Baja Boot. This story is about racing to save lives. James Glickenhaus and son Jesse, of Scuderia Cameron Glickenhaus (SCG) fame, have offered their Danbury, Connecticut, property to the Danbury Hospital if extra space, beds, power, and other items are needed during the COVID-19 outbreak. The boutique manufacturers of exotic high-performance racing and road cars have put aside their imminent plans to add to their small fleet of race-winning supercars at a newly-completed factory building on the grounds of the Danbury Municipal Airport. Jesse is also working on the urgent needs for protective masks.

“We offered our Connecticut factory to the Danbury Hospital,” said Jesse, 38, during a recent interview, who is a Founder and Managing Director of SCG. Both Jesse and his father, James, 69, who is a Founder and Managing Member of the company are not only entrepreneurs but have also been called dreamers and builders of dreams. The duo, who work together on all significant projects, became motivated to help with the urgent shortage of masks.

“We were inspired by an article in Vogue about a woman, whose sister a NICU nurse, wasn’t given a mask for a birth; by our friend who spent a recent week, during his vacation from work, driving around the state looking for protective equipment for his anesthesiologist group; and by the numbers of required masks, available masks, and the limited ability to scale production,” explained Jesse. “I was upset with the FDA’s recommendation to use a “bandana” or to reuse single-use N95 masks and soak them in hand sanitizer. We are better than this as a country.”

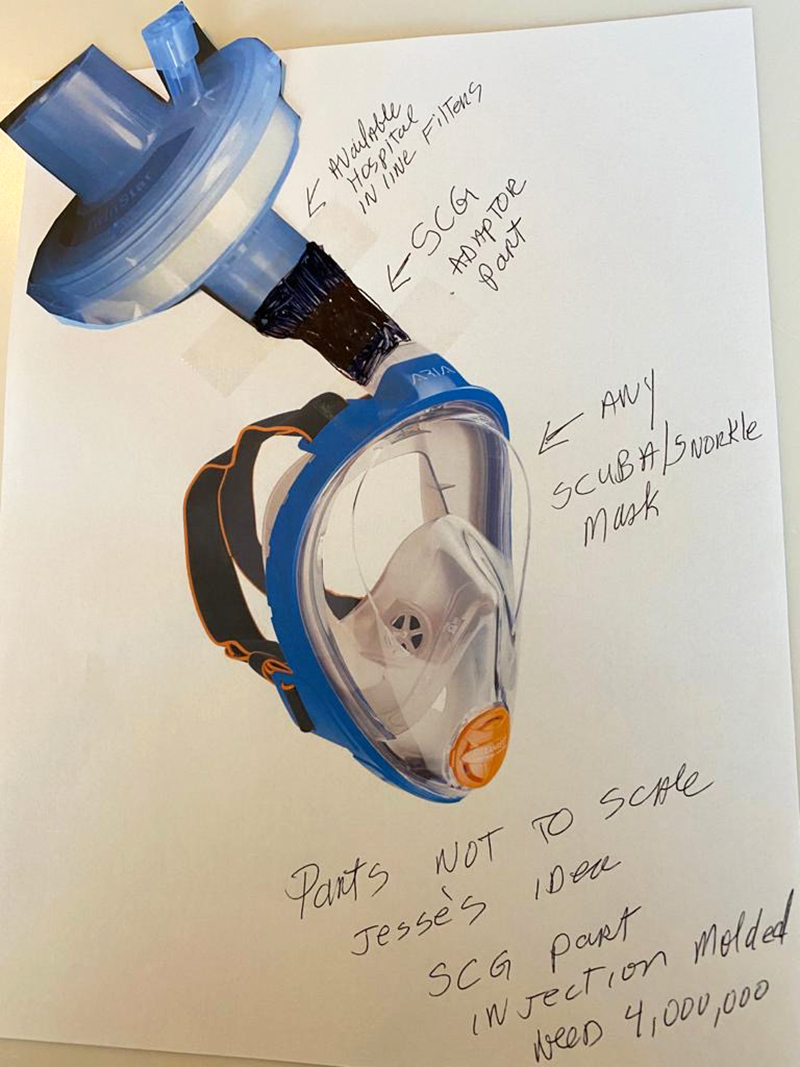

The idea was hatched to repurpose existing full-faced snorkels to provide reusable personal protective equipment for healthcare providers. “In my mind, if a mask could be fitted with a filter, it would be better than a bandana. Since hundreds of thousands of full-faced snorkel masks were likely sitting in stores, such as Walmart, Dick’s Sporting Goods, WestMarine, and Amazon and, since no one was buying snorkels for recreation any time soon, it seemed like a quick way to scale up some protection quickly.” First, we reached out to friends who are doctors and asked for their thoughts, inputs, potential problems, etc. The doctors all loved the idea. They thought it had several advantages-certainly over a bandana- and even over current N95 masks. The snorkels provide, they felt, better full-face protection for the eyes, nose and mouth. Since they are designed to have watertight and airtight seals, this would protect against aerosolized particles. Finally, since the air filter was on the top of the head facing backwards, it would seem to provide another safety factory because the healthcare providers would not be pulling air from right next to the patient. Once we decided it was a solid idea, we went about turning it into reality.”

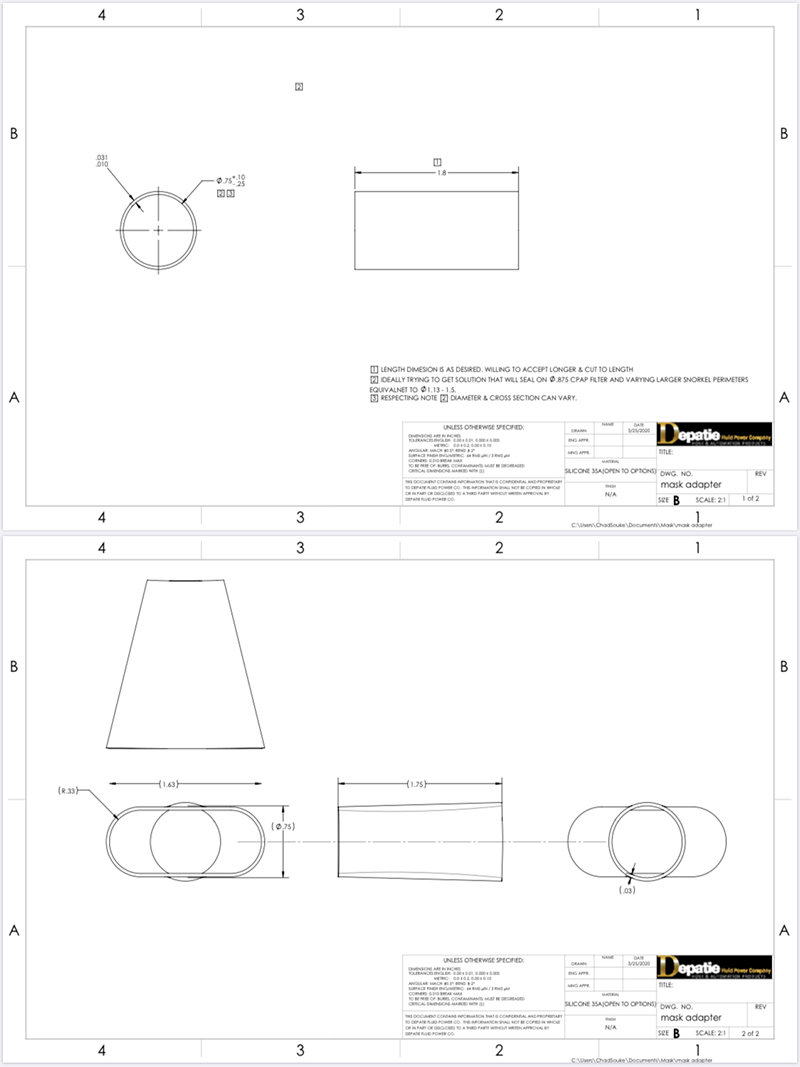

Glickenhaus reached out to a mask company and then to friend Chad Souke, a mechanical engineer who invented the hydraulic lift system for medical cots for Stryker. “He was inspired to help and engineered a universal adapter that could connect any snorkel mask to any universal hospital filter (CPAP filters that are standard sized fittings, available in every single hospital, and filter to a better standard than N95 filters). We were willing to manufacture our own tooling to manufacture the part, and to pay for that tooling, but first we wanted to see whether we could make any existing part work. We thought of all sorts of fittings in cars for water, fuel, oil, etc. Then we decided high temperature silicone tubing might work. We ordered several different sizes, tested them, and realized it would work very well and form an airtight seal between the mask and the filter.”

After reaching out to connections at the US Chamber of Commerce, and connecting with Walmart, Amazon, and other retailers, it became clear that for the large retailers to become involved, the device would need FDA approval. “We then reached out to all our connections, and have been working now to file our application for Emergency Use Authorization for emergency FDA approval of these masks. In the meantime, we decided to put out a do-it-yourself video, until there was FDA approval. The process is moving along, and we have received several updates from the Government”.

James Glickenhaus, seen here on the right next to his son, Jesse, is an American film producer, financier, director and automotive entrepreneur. Glickenhaus & Co., is a family partnership originally started by his father Seth. Glickenhaus wrote, directed and produced a number of films in the 1980s and 1990s, including The Exterminator and the Jackie Chan vehicle The Protector. He is an avid collector of former racing vehicles, especially Ferraris. His coachbuilt Ferrari P4/5 by Pininfarina has been extensively covered by national publications like Car and Driver.

As the developers began answering questions for information about the masks from around the world, from Australia, Indonesia, India, to New York City’s Department of Health, they then posted info, pictures, and videos of the masks on Facebook, Instagram and twitter. They were also contacted by Mahindra. “They shared that they were making for free clear polycarbonate boxes to help protect doctors during intubation. They asked us to help get the word out, so we posted about those, and since then we have connected hundreds of doctors and hospitals around the world to help them get intubation boxes.” Additionally, a doctor from the anesthesiology department of a major hospital in Connecticut has reached out to learn more about the masks.

Goodwill work and participating in fundraising events for community organizations for this supercar builder is not new, who also has policies to support women in motorsports and is committed to running an all-women’s factory Boot team in the next Baja 1000 and has a strategic partnership with Aurora Straus’ Girls With Drive organization.

Jesse Cameron-Glickenhaus, 38, is an actor, known for Slaughter of the Innocents (1993), Timemaster (1995) and The Protector (1985).

In addition to the Baja Boot, SCG is heralded for its sports cars and hypercars that have collected wins in racing since 2011, in events such as GT3 and the GT4S 24 hours of Nurburgring; with eight seasons of endurance racing, the company has achieved eight 24-hour finishes with three first-in-class, one second, and one third. A goal now is to win LeMans as the first Americans since Ford’s win in 1967 with a MKIV.

A new goal has also come to the forefront. Jesse and James are now racing to save lives and are eager to delay production of their vehicles at their factory in Connecticut to do so. It’s a finish line they want to cross with many helping hands and a very different type of win.

*Glickenhaus North American Racing (GNAR) is a full-service motorsports company offering sales, service, storage, concourse and track support as well as collector car advisory services focused on rare and collectable, sports, race and exotic automobiles. Learn more about GNAR by visiting www.glickenhausracing.com/.

OutdoorX4 Magazine – Promoting responsible vehicle-based adventure travel and outdoors adventure