Understanding the anatomy of a powered winch

Today’s most popular powered winches are capable of moving a vehicle or object with the vehicle’s transmission in neutral. In other words, modern off-road winches use the electrical or hydraulic energy generated from a vehicle’s engine, without drawing power directly from the engine’s driveline (transmission, driveshafts, wheels, etc.). PTO (Power Take-Off) and wheel-driven winches that do draw power directly from the engine’s driveline are a thing of the past.

Winch

There are two contemporary powered winch types used today – electric and hydraulic. An electric winch obviously uses energy from the vehicle’s battery and the engine’s alternator. Hydraulic winches require energy from the engine’s hydraulic power steering pump.

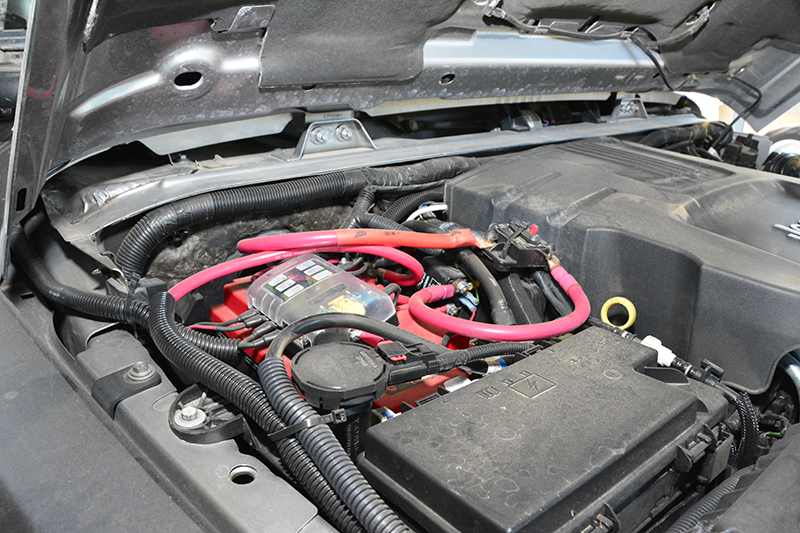

Electrical winch properly mounted on an aftermarket bumper.

Electrical Winches

An electric winch is exactly as its name suggests – it is electrically powered by the vehicle’s battery. The engine’s alternator replenishes the battery with electrical energy. An electric winch does not need the engine to be running, but without the replenishment of electrical energy from the engine’s alternator, a winch can quickly use up the stored electrical energy in a single battery. This is why many off-roaders and overlanders keep their engine running while winching, upgrade their vehicle’s stock battery, and add a second battery with a dual-battery isolator or computerized battery minding system. Regardless of whether you have a single or dual battery set up, electric winches need extreme deep cycle batteries, while your vehicle needs a battery with lots of cranking power. To get both features, you’ll need an exceptional battery. The battery brands Odyssey and Optima fit this category. Buy the very best battery you can.

If you purchase an electric winch for your vehicle, upgrade the stock battery to a deep cycle battery with lots of cranking power. Also, always connect both winch electrical cables, positive and negative, directly to the battery. Do not connect the negative cable to ground on the frame.

When winching for extended periods of time, an electric winch has an Achilles heel – its motor. This component can fail if you don’t pay close attention to the heat build up while you winch. Electric winches don’t have a 100 percent duty cycle (like a hydraulic winch) and need a rest occasionally from their work. This “rest” allows the electric winch cool down and build up an electrical reserve in the battery from the engine’s alternator.

Of the two types of modern, recreational powered winches – electrical and hydraulic – the electrical winch is by far the most popular. More companies make recreational electrical winches than hydraulic. There are also more models of electrical winches on the market. This is because electrical winches are the best choice for the majority of off-roaders and overlanders. First, compared to hydraulic winches, the installation of an electrical winch is less intimidating to most home garage mechanics. Second, electrical winches are more ideal for leisure and occasional users. As a recreationalist you don’t typically need to winch an extended period of time. Typically, you will pull yourself out from a stuck situation or over difficult terrain and move on. However, if you need to winch for hours on end, then perhaps you should consider a hydraulic winch.

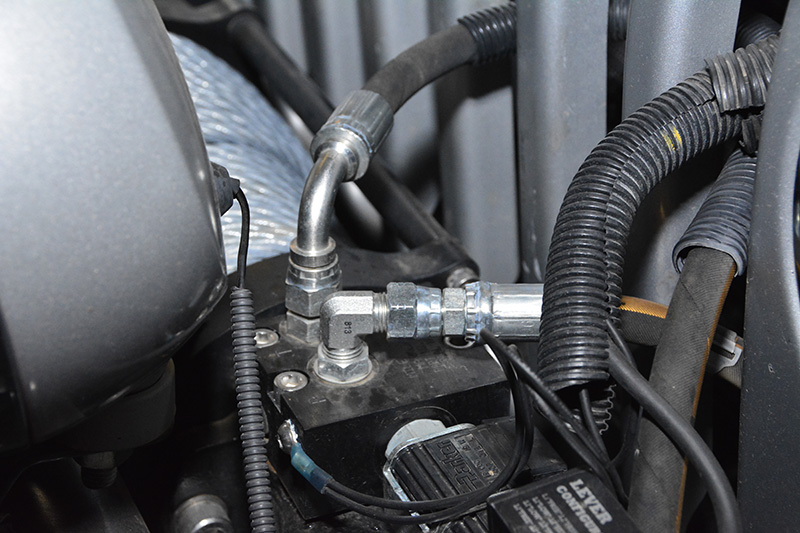

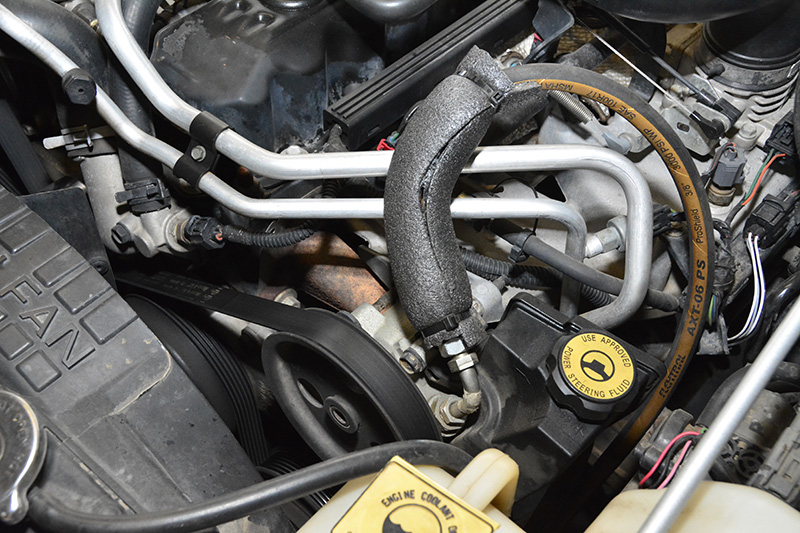

A hydraulic winch from Mile Marker mounted on an aftermarket bumper. Note how the winch is plumbed into the vehicle’s power steering pump.

Hydraulic Winches

Hydraulic winches draw their power from an attachment to your OEM power steering pump, a device that is very powerful and reliable. Hydraulic winches can be used in practically all vehicles and under almost every condition. For example, these winches work well in the worst temperatures, from -50° F/-45°C to 135°F/57°C. They can also function underwater – totally submerged.

Hydraulic winches have four basic advantages over electric winches. First, a hydraulic winch has a very high duty-cycle. Unlike an electric winch that needs period rests, a hydraulic winch can run for quite sometime without getting overheated. Second, the line speed of a hydraulic winch is about the same regardless of load. Winch line speed will slow with heavier loads on an electric winch. Third, a hydraulic winch has no “run-on.” When you stop the winch, it stops line pull immediately. Contrast this to an electric winch that still “rolls” a bit of winch line on its drum after you stop the winch with your controller. Fourth, a hydraulic winch can run continuously without any battery drain.

A downside of all hydraulic winches is that your engine must be running to turn the power steering pump, and hence create hydraulic power for the winch. A dead engine means a dead winch. Further, when the engine is not running, some hydraulic winches will not hold a load.

On some vehicles, you may need to upgrade your power steering pump to a high volume kit to effectively run a hydraulic winch. Research this regarding your make and model vehicle prior to deciding to purchase a hydraulic winch.

Because these winches need to be hooked into a power steering pump, they are a bit more intimidating to install. However, if you are handy with a wrench and can read instructions, installation is not that difficult.

At this time, Mile Marker is the only company producing hydraulic winches for the recreational off-road market. These winches are waterproof, have two-speeds, and are extremely low profile. Even though more electric winches are produced each year, hydraulic winches are great performers. If you plan on doing lots of winching, a hydraulic winch should be strongly considered.

Winch Anatomy and Terminology

To intelligently purchase the right winch for you and your vehicle, plus to winch effectively, you need to become familiar with the main structural components of a winch and its inner workings.

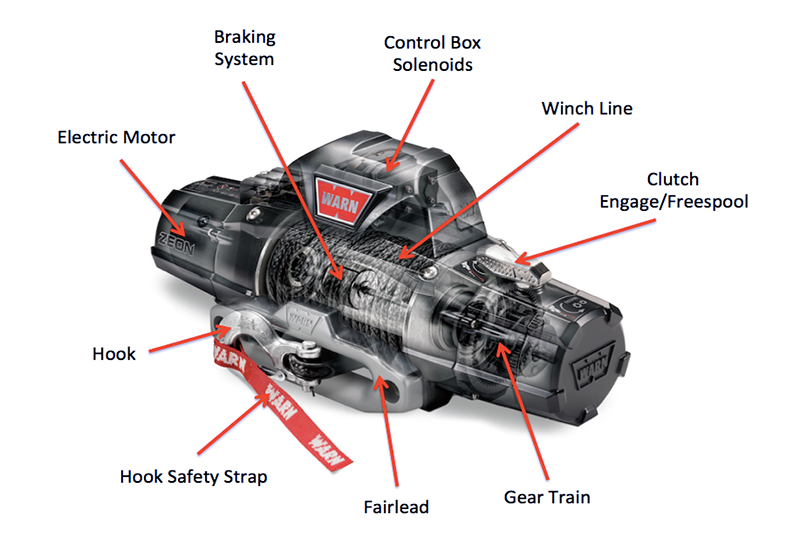

Image courtesy of WARN

The cutaway illustration of a typical electric winch, plus the photos provided here, give you the location of the important structural components and parts.

Winch Controller. Typically, a winch controller is a low-voltage, wired control that plugs into the winch control box. It allows you to stand a safe distance from the winch when controlling the direction of the winch motor, drum, and line – winch in or winch out. Some of the controllers also provide you with winch motor heat warning information. Most controllers are connected to the winch control box via a long cable and simple plug-in connector. Some winch manufacturers have wireless remote control accessories. These remote controllers include a wireless receiver that fits on the standard winch connector (or is integrated in the electronics within the control box), plus a fob-style “in-out” push button that can be placed on your key ring or mounted in your vehicle’s cab. Some controllers provide users with additional information, such as motor temperature, battery volts, and line speed.

Winch controllers can be wired and wireless.

Control Box. Winch control boxes contain all the electronics of a winch, plus the winch controller outlet. They may be actual boxes that are mounted on or near the winch itself, or the electrics may be mounted inside the sealed winch housing. Many are waterproofed (to greater or lesser degrees) to protect them from the elements. The control box houses the winch solenoids, heavy-duty relays, or a direct switch to control the power going to the winch motor.

Clutch. The clutch control could be a lever on the winch itself, or a button on a winch remote. An electric winch clutch control only has two settings – Freespool and Engaged. The clutch allows you to manually disengage the spooling drum from the gear train – this is called freespooling. The freespool clutch setting allows you to manually pull line off the winch drum by hand with no resistance from the winch motor and gearing. When you wish to power-pull an object using the winch motor, you engage the spooling drum and gear train. A hydraulic winch has four settings, with two levers. The two levers turned according the manufacturer will place the hydraulic winch in four modes – freespool, low gear, high gear, or lock.

Speed Control Lever. Most hydraulic winches have a two-speed control lever. There’s a high-gear setting for lighter loads, and a low gear for maximum pulling power.

Motor. Powered by a battery or hydraulic energy, the winch motor provides power to the gear mechanism, which in turn rotates the winch drum, and winds the winch line in or out. Electrical off-road winches use two types of DC motors – permanent magnet motors, and series wound motors. Both have advantages and disadvantages, but most off-road winches use series wound motors. Series wound motors on winches are more heavy duty than permanent magnet motors, they are more tolerant to heat, and work best at lower ambient temperatures. Their downside is that they use a higher amp draw from your battery. This often requires battery upgrades or dual battery systems to effectively power series wound winch motors. For more information on the two types of DC motors, read the section at the end: Series Wound or Permanent Magnet Electric Winch Motors… What’s the Difference?

Gear Train. Winches use a gear train to transfer motor power to the drum. The gear train converts winch motor power into a more powerful pulling force through gear reduction. Gear reduction is labeled as a gear ratio, such as 156:1 – meaning 156 rotations of the winch motor to 1 drum rotation. Gear reduction increases the pulling force used to powerfully rotate the drum resulting in the spooling out or in of the winch line. There are three main types of gear trains found in most off-road winches – worm, spur, and planetary gears. Each has its mechanical advantages and disadvantages. A worm gear train is quite simple, with few moving gears. There are often two gears – the smaller worm gear itself, and the larger worm-wheel gear. Spur gear train winches are reliable with fast line speed. Their downside is difficulty in holding a static load when winching is stopped. To compensate for this downside, spur-style winches need to employ a strong braking system. The only remaining recreational powered winch with a spur gear train is the venerable and very capable WARN 8274-50. Planetary gear trains are the most common for off-road winches. They are compact, lightweight, and cost less to manufacture.

Drum. Sometimes called the winch spool, the winch drum is a hardened, hollow metal cylinder, around which the winch line is wrapped. The winch drum is driven by the winch motor and gear train.

Braking System. The winch brake system is automatically engaged when the winch motor is stopped and there is a resistance load on the winch line. The mechanical brake system prevents unwanted winch line from being spooled out when the winch is not powered. Without the brake system, slack winch line could occur when the winch is not powered. On most contemporary electric winches, the brake system is either inside the hollow winch drum, or at the end of the gearbox. Winch brake systems act much like the drum brakes on your vehicle’s wheels – they create heat. If you intend on using synthetic rope winch line, consider purchasing a winch that does not have its brake system located inside the drum. Excess heat transferred to the drum can cause unprotected synthetic rope to melt on the first layer. Companies that do sell synthetic rope winch line with winches that have braking systems located inside their drums, place heat protection around the rope that could contact the drum itself on the first layer.

Winch Line. Winch line is wrapped around the winch drum and fed through the fairlead (explained below). One end of the winch line is physically attached to the drum with a screw or bolt, the other end has an open thimble with either a winch hook or winch line shackle mount (explained later). Winch line can be steel cable or synthetic rope. Which to choose is a topic covered a bit later, along with how to choose the correct size winch line.

Fairlead. The fairlead guides the winch line onto the winch drum. A fairlead minimizes winch line wear as the line enters or leaves the winch, particularly at an angle. Fairleads are typically of two types – roller and hawse. Roller fairleads have four metal or nylon rollers on their tops, bottoms, and sides to protect the winch line. Roller fairleads with metal rollers may be used with steel cable winch line, or if new may be used with synthetic rope. Roller fairleads with nylon rollers may only be used with synthetic rope. Hawse fairleads are smooth, machined aluminum with no rollers, and are only used with synthetic rope style winch line.

Roller Fairlead

Hawse Fairlead

Hook or Winch Line Shackle Mount. At the end of most winch line you’ll typically find a grooved-metal eyelet fitting, on which the steel cable or synthetic rope winch line is wrapped around and fastened back onto itself. Collectively, this is called the winch line thimble. There are gusseted and un-gusseted thimbles; with gusseted being the strongest. Winch line thimbles protect the line from getting crushed or overstressed. A winch hook or a winch line shackle mount can be placed on the end of the thimble. It is the winch hook or winch line shackle mount that is attached to other pieces of recovery gear, allowing the winch to pull against the gear.

This photo shows several winch hooks. Left to right – Stock clevis sling hook, positive locking or safety hook (the best), WARN’s Epic throat latch clevis sling hook, two standard throat latch clevis sling hooks.

Many off-roaders and overlanders are dumping their winch hooks for winch line shackle mounts, such as those made by Factor 55. Winch line shackle mounts allow you to set up safer rigging, using hookless closed-loop winching.

Many off-roaders and overlanders are dumping their winch hooks for winch line shackle mounts, such as those made by Factor 55. Winch line shackle mounts allow you to set up safer rigging, using hookless closed-loop winching.

Hook Safety Strap. If a winch hook is attached at the end of your winch line, it should have on it a safety strap. Safety straps are typically about 12 inches/30 centimeters long, allowing you to keep your fingers away from the fairlead while winch line is being spooled in. When a hook is getting close to the fairlead, hold the hook safety strap at the end to protect your fingers and hands from getting crushed in the powerful winch.

Selecting the Correct Winch for Your Vehicle

Don’t allow your winch purchase to be spontaneous. You need to answer several key questions, and decide on a few winch attributes to intelligently find a winch to meet your needs. Answer these questions:

What is my budget?

How much winch do I really need?

How often and how hard might I use my winch?

What type of winch am I considering – electric or hydraulic?

What type of winch line do I want – steel cable or synthetic rope?

What are my mounting options based on the fit and weight of the winch?

What are my mounting options based on the fit and weight of the winch?

Can the winch I’m considering be serviced?

What other equipment might I need to make a winch work with my vehicle?

Next, evaluate the six basic attributes of the winch you have in mind. List out these attributes from the winch specification sheet.

Winch Capacity (Rated Line Pull). The winch capacity, or rated line pull, is the most touted number attached to a winch by its manufacturer. The number is really a combination of the winch capacity, plus the tensile strength of the winch line sold with the winch. Mechanical capacity is the maximum pulling capability in pounds or kilograms of a winch during a single line pull (no pulley blocks) on level ground. This maximum winch rating is only available when a single layer of winch line is on the drum. The question now must be asked, “What winch capacity do you need off-road?” The standard answer to this question is: Purchase a winch that has a capacity 1.5 to 2 times the gross vehicular weight rating (GVWR) or gross vehicular mass (GVM) of your vehicle. Using this guide, let’s say the GVWR of your vehicle is 5700-pounds/2585-kilograms. You would need a winch with a rated line pull of between 8550-pounds/3878-kilograms to 11400-pounds/5170-kilograms. Winching experts will warn you to err on the high side relative to rated line pull when purchasing a winch.

12 Volt DC Performance Specifications. Use this information to compare one winch with another. Generally, this information is in a table comparing line pull in pounds/kilograms, line speed, and motor current (amps used).

Motor. Most electrical winches have series wound motors. See the sidebar comparing series wound and permanent magnet motors.

Line Speed. Line speed varies primarily on the weight of the object being pulled and the amount of energy provided to the motor. Some winch models focus on a fast line speed for racing competition, but most models of winches vary considerably. Faster winches with good pulling power requires a powerful motor, large gearing, and lots of amps from the vehicle’s electrical system. Extremely slow line speed can make for very anxious recoveries and impatient respooling of line on the winch. Examine line speeds along with amp draws to determine the right winch for your vehicle’s electrical system.

Recommended Battery. If you are purchasing an electric winch, you need to pay close attention to this specification. The extra demand a winch can put on your electrical system will be large, and it’s possible to exceed the system’s stock capabilities. If possible, get a larger than recommended battery and upgrade your alternator to a high output alternator. Further, consider installing a dual battery system with an isolator and computerized battery minding system.

Length and Diameter of Winch Line Provided. On a winch specification sheet, it will list the type of winch line included with the model winch you are purchasing. It will also list the length of the winch line, and the diameter. If the length of line provided by the manufacturer is at or under 75-feet/22-meters, consider getting at least a 50-foot/15-meters winch line extension for use in the field. If you purchase a winch with 100-feet/30-meters or more winch line installed on its drum, it may be difficult to remove an appropriate number of layers of winch line from the drum when setting up a pull. The more layers of winch line you have on your drum during a pull, the harder the winch has to work. It you purchase a winch with less than 75-feet/22-meters of winch line on the drum, you may have trouble reaching anchor points. The point here is that simply purchasing a winch with a great deal of winch line on its drum is not always the right solution.

Winch Mounting Options

There are two basic mounting options for your winch – permanently mounted on your bumper, or hitch-mounted. The majority of off-roaders and overlanders prefer to permanently mount their winch on their front bumper. Many aftermarket manufacturers make bumpers that are winch-ready. With most of these aftermarket bumpers, you simply bolt on your winch, hook up the battery cables, and you are ready to go. Some vehicle manufacturers also sell winch-ready bumpers right from the showroom floor. Others even include a winch in the sales price.

Hitch mounted winch. Photo Courtesy of WARN

Hitch mounted winch cradles are sold as an accessory by most winch manufacturers. These cradles mount directly to a front or rear hitch point on a vehicle. This mounting option is great if someone wants to move his winch from one vehicle to another. Some off-roaders who wish to have a winch in the back, as well as the front will go with this option. If a winch is mounted in the rear of a vehicle, battery cables need to be routed to the rear for connection to the winch. Often, these cables have quick disconnects so the winch and cradle can be moved from one hitch to another. Hitch mounted winches also work well for work trucks, and off-roaders that only occasionally use their vehicle in the backcountry.

Series Wound or Permanent Magnet Electric Winch Motors…What’s the Difference?

All direct current (DC) electric motors have one set of coils, called an armature. This armature rotates inside another set of coils (Series Wound motor), or a set of permanent magnets (Permanent Magnet motor). Applying a voltage to the coil(s) produces a torque in the armature, resulting in horsepower (motion).

Simply put, most winches for large 4WD vehicles have series wound electric motors. Permanent magnet electric motors are generally found on less expensive, smaller, more portable, ATV, and motorcycle winches. Here’s why.

Permanent magnet DC motors are inexpensive to produce, until greater horsepower and duty cycle is desired, then the price advantage shifts somewhat to series wound DC motors. A permanent magnet DC motor will pull about the same as a series-wound DC motor, but at less of an amperage draw on the battery and charging system (thus better for ATVs and motorcycles). However, as winching time and load is increased using a permanent magnet DC motor, excessive heat is produced. As the permanent magnet DC motor gets warmer, the power will drop as the amperage draw increases. Also, the magnets in permanent magnet DC motors can lose their magnetism over time and repeated use. Compared to series wound DC motors, permanent magnet DC motors are also less tolerant of cold ambient temperatures, generated heat from use, and external rough abuse.

Series wound DC motors are powerful and efficient at high speed and generate the most torque for a given current. Per current draw and torque, series wound DC motors generate less heat than permanent magnet DC motors. Also, the amperage draw on a series-wound DC motor will stay the same throughout the duty cycle.

* OutdoorX4 Magazine – Promoting responsible 4×4 adventure travel and outdoor recreation