Discover Offroading

This web-article is a follow up to the printed piece “Recover With Confidence – Conducting a Stuck Assessment and Formulating a Recovery Plan” in Issue 14 of OutdoorX4. Before you work through the example stuck scenarios presented here, read the magazine print article in total. Until you understand the print-article, the scenarios outlined here may read like a foreign language.

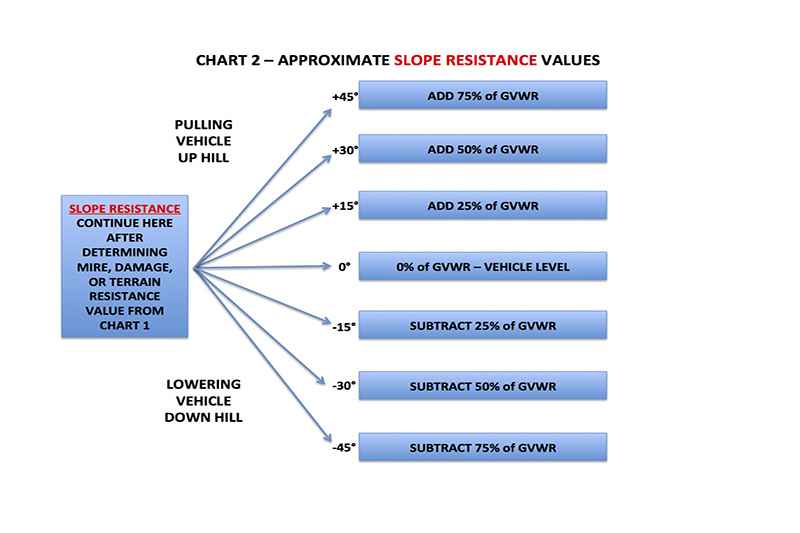

CORRECTION NOTE: There is a minor correction to the title of Chart 2 in the printed version of the article “Recover With Confidence – Conducting a Stuck Assessment and Formulating a Recovery Plan.” The title of Chart 2 in the STOPA Checklist should be: Approximate Slope Resistance Values. There are no “Pulley Block” resistance values found anywhere on the chart or in the STOPA checklist. Some winching worksheets found in literature add in a resistance value for each pulley block in a rigging setup to the total load resistance number. This is not necessarily wrong, but with today’s modern pulley (“snatch”) blocks it’s really not needed, according to Wreck Master, the preeminent North American tow truck training company. The Surface and Slope resistance values used in the STOPA Checklist are all that are needed to calculate approximate winching loads. Wreck Master’s resistance values have been scientifically determined by quantitative methodology and validated by years of in-field experience.

Important Article Side Notes

There are only so many words an author can jam into a printed magazine article. Therefore, some important notes are left out or cannot be elaborated on. The following are points to consider regarding the article “Recover With Confidence – Conducting a Stuck Assessment and Formulating a Recovery Plan” in Issue 14 of OutdoorX4 magazine.

The Article is Written Specifically For the Inexperienced. The article is written for off-roaders and overlanders that don’t have much, if any, actual winching or general recovery experience. As the author, I acknowledge that seasoned recovery veterans (including myself) will work through the STOPA Checklist steps in their minds. We don’t need no stinkin’ checklist! In fact, you won’t need a checklist either once you gain some recovery experience. It is for this reason I continually encourage readers to gain actual experience by taking a 4WD course from a professional trainer.

Vehicle Recovery

Further, experienced overlanders rarely do any math to estimate the loads put on recovery equipment and vehicles when attempting to get a vehicle unstuck. Experience allows them to mentally estimate the loads involved. When bogged, experienced overlanders will simply: 1) Audit the situation, 2) Carefully rig a recovery setup, and 3) Give it a try. In most cases, their experience will serve them well and they will get a vehicle unbogged in only one attempt. However, even the most experienced recovery professional will tell you that it took a few missteps and/or failures to arrive at their experience level. The STOPA Checklist can help overlanders without much recovery experience avoid dangerous mistakes while gaining valuable recovery experience.

The Article’s Purpose. The primary purpose of the article is to get those that haven’t performed many recoveries to simply think clearly about bogged situations. This is in sharp contrast to simply hooking up a winch or kinetic energy recovery rope or strap and start pulling on a stuck vehicle (like so many do). There are great forces at work with these types of recovery efforts. If these forces exceed the working load limit of recovery equipment and accessories, bad things can happen. Winches can begin to smoke or quit, shackles can deform or break, rope can fail, and straps can tear. How large are these forces? They are huge. For beginners, the word huge is ambiguous. As an educator, I feel compelled to provide beginners with a real number – even though it’s an approximation. An actual load resistance number can exemplify and highlight the power of these forces to the uninitiated. To find an approximate resistance value, one needs to do a small amount of math.

“Approximate” Resistance Values. There are many variables related to the nature of an actual stuck situation. As a specific example, mud in one geographical location will be different than mud somewhere else. Adding to this variability, are many types of mud one can get stuck in. These different characteristics and types of mud will provide different resistance values. Point is, in the natural world it’s all but impossible to accurately calculate resistance values for any one stuck situation. The only way to arrive at a precise resistance value for any singular recovery effort is to measure the pull with a dynamometer (a device using for such measurements, particularly in the hoisting industry). Short of using this device, any resistance value calculated is purely approximate.

In my humble opinion, the calculation of approximate resistance values in the STOPA Checklist serve four important purposes. They:

- Are of teaching value for those beginning to learn the dynamics of recovery and stuck extraction.

- Can help the inexperienced understand the forces involved in practically all recovery efforts.

- Can help the inexperienced avoid recovery missteps and failures.

- Can help those that are nervous and running on adrenaline to focus on the recovery effort at hand so as to avoid exceeding the working load limit of recovery equipment and accessories.

Add a Safety Margin. Because there are so many variables inherent to any one type of terrain or recovery situation, consider adding a safety margin to your total resistance calculation. A safety margin of 25% is used in the scenarios outlined in this article.

Use the Checklist – Forget the Math. Don’t get bogged down in calculating the resistance values outlined in the STOPA Checklist. Calculating a total resistance value is only a small component of the entire checklist. Calculating a total resistance value is an important starting point for developing a final recovery plan, but don’t miss the forest by staring at a tree. What is important is the checklist itself. In a nervous and anxious recovery situation, deep in the remote backcountry, adrenaline can get the better of you. This is especially true if you are solo without other vehicles around. The checklist forces you to slow down and focus on formulating a thoughtful recovery plan. Running around at Mach 2 with your hair on fire after a vehicle gets stuck or rolls over is the antithesis of what you should be doing. Checklists can calm the overactive and misdirected mind in times of trial and tribulation.

Practice Scenarios

By working through the scenarios outlined here, you will better understand the Approximate Recovery Resistance Values portion within the Observe step in the STOPA Checklist. All scenario calculations are completed in imperial measurement (pounds) for simplicity. The resistance calculation methodology is the same for metric measurement in kilograms.

General Information for Scenarios One and Two

- You are traveling solo, so self-recovery is needed.

- The Gross Vehicle Weight Rating (GVWR) of the stuck vehicle is 5,000-pounds (like a Jeep TJ).

- The stuck vehicle has a 9,000-pound rated winch.

- The vehicle is stuck up to its wheel hubs in mud, and its wheels are not damaged; it can roll.

- The vehicle is on a 15° slope.

- The initial recovery plan to lower tire pressure and use traction boards has failed to get the vehicle unstuck.

- The secondary recovery plan is to use a winch. Deciding to use a winch, you need to calculate your total recovery load.

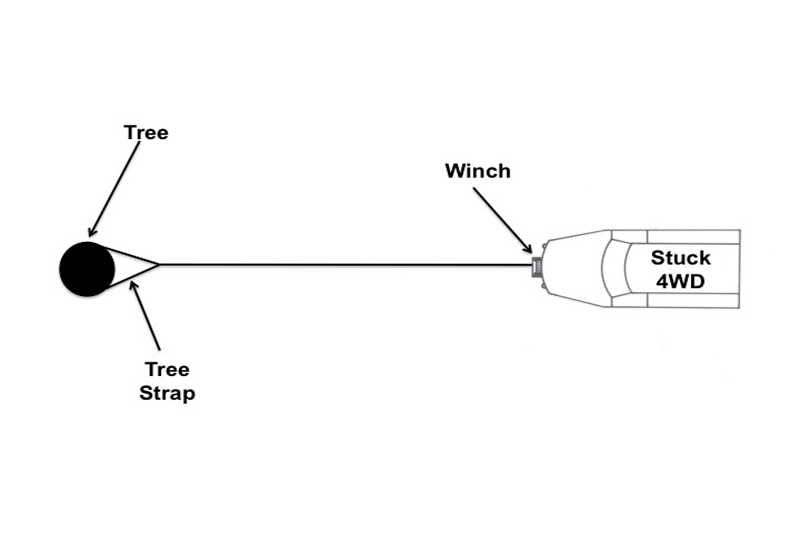

- The winch connection is made using a tree as an anchor.

Scenario One

After using the STOPA Checklist, you formulate the following recovery plan and quickly calculate these resistance values.

- Find the Mire Resistance. The stuck vehicle is wheel depth mired in mud (stuck up to your axle hubs), so add 100 % of the vehicle’s GVWR = 5,000-pounds.

(Since the vehicle is mired in the mud, you disregard Damage Resistance and Terrain Resistance Values; use the Mire Resistance value ONLY.)

- Find Slope Resistance. The stuck vehicle is on a 15° slope, so the added slope resistance is 25% of the GVWR = 1,250-pounds. Calculation: .25 x 5,000 = 1,250-pounds

- Safety Margin. Add 25% of stuck vehicle’s GVWR to your total resistance calculations. Calculation: .25 x 5,000 = 1,250-pounds

- TOTAL Estimated Resistance. 5,000 Mire Resistance + 1,250 Slope Resistance + 1,250 Safety Margin = 7,500 total pounds of approximated resistance.

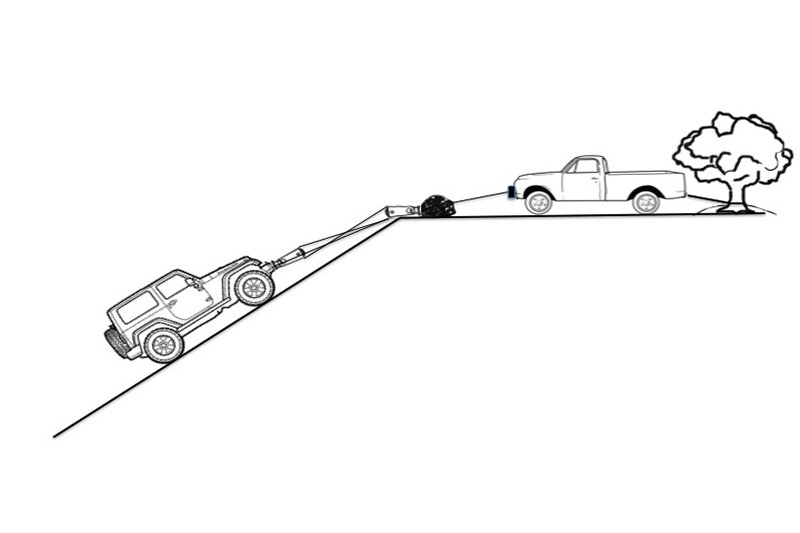

Scenario 1 Illustration

- Find the Actual Pulling Capacity of Your Winch. To reach the tree you will pull against, you take off all but 4-layers of winch line from your winch drum. This means your 9,000-pound rated winch now has only 70% of its original capacity – it is now a 6,300-pound capacity winch. Calculation: 70% of original capacity means it lost 30% of its total winching capacity. Therefore the calculation is as follows: 9,000 – (9,000 x .30) = 9,000 – 2,700 = 6,300.

- Recovery Plan. The winch has a calculated pulling capacity of 6,300-pounds. The total estimated resistance is 7,500-pounds. The single-line pull from this winch will not move the stuck vehicle. A secondary plan is needed. See Scenario Two.

Scenario Two

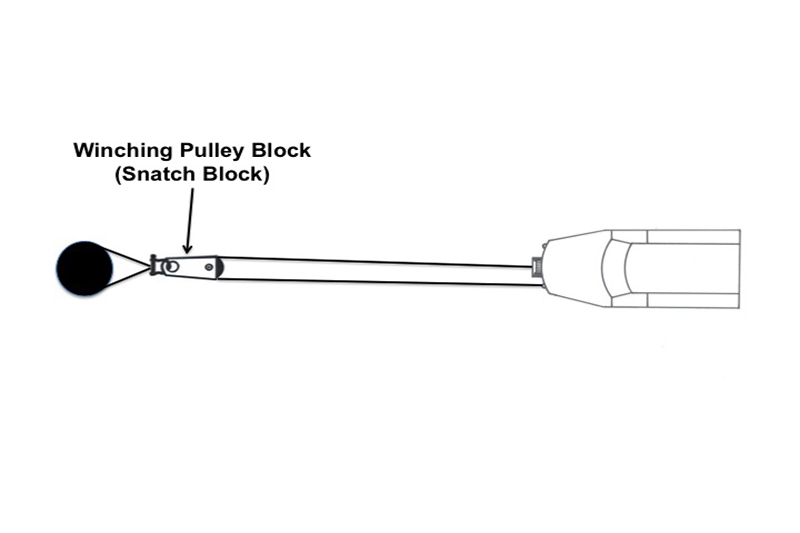

The total calculated resistance in this scenario adds up to be the same value as in Scenario One – 7,500-pounds. The recovery plan in this scenario differs from Scenario One since it involves the use of a single moving pulley block. The winch rigging is a double-line pull. The winch line is placed through the pulley block, and then connected back to the vehicle.

Scenario 2 Illustration

- Find the Actual Pulling Capacity of your winch. To perform a double-line pull using a pulley block, you successfully take off all but one layer of winch line on your winch drum. This means your 9,000lb rated winch is capable of pulling to its total capacity – 9,000lbs.

- Recovery Plan. A double-line winch pull will be successful. By adding a moving pulley block to the rigging configuration, the winch becomes more efficient. It is now capable of mechanically moving an 18,000lb load. With this riggin, the winch will easily move (although at a slower speed) the 7,500lbs needed to get this vehicle unstuck and out of the mud.

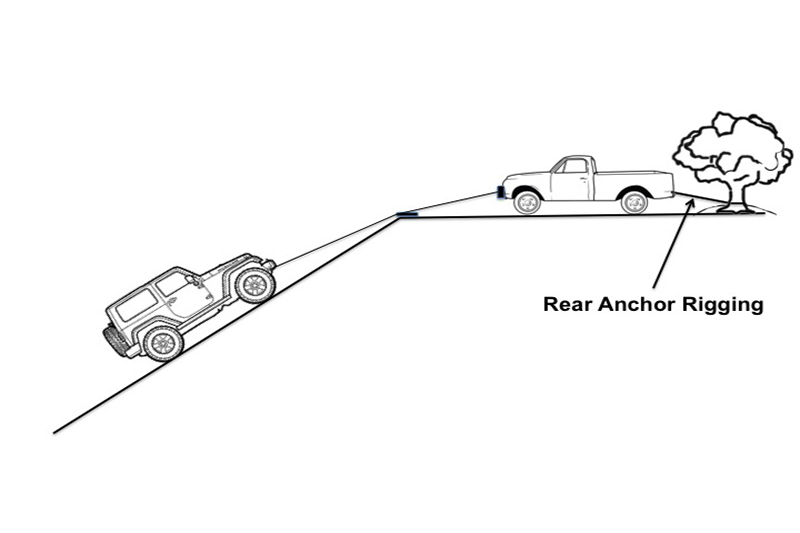

General Information for Scenarios Three and Four

- You are traveling with another vehicle. Therefore, vehicle-assisted recovery is possible.

- The Gross Vehicle Weight Rating (GVWR) of the stuck vehicle is 5,700-pounds (like a Jeep two-door JK).

- The Gross Vehicle Weight Rating (GVWR) of the recovery vehicle is 4,600-pounds (like a Toyota Tacoma). Since this vehicle is lighter than the vehicle being recovered, parking brake and wheel chock use is mandatory to keep the vehicle from sliding while winching. Even with brakes and wheel chocks, the lighter vehicle may still move. Because of this, you will set up a rearward safety anchor on the recovery vehicle. (Note: If the vehicle has an automatic transmission, place it in neutral for the pull. You want to avoid putting extreme pressure on the transmission’s parking pawl during the pull. Doing so may damage the transmission.)

- The recovery vehicle has a Class III trailer hitch (8,000-pound WLL). With the additional weight of the recovery vehicle, this hitch along with the rearward anchor is a legitimate safety measure should the recovery vehicle begin to move.

- The recovery vehicle’s frame is solid, and has a receiver shackle bracket for a rear connection point to the anchor.

- During winching operations, the recovery driver should monitor possible vehicle movement during winching

– The recovery vehicle has an 8,000-pound rated winch. The stuck vehicle does not have a winch.

– The stuck vehicle is on a steep hill with a measured 25° slope.

– The recovery vehicle is on level ground at the top of the hill, positioned back a bit from the hill’s edge. The front of this vehicle is pointed towards the downhill slope – winch towards the stuck vehicle.

Scenario Three

After using the STOPA Checklist, you formulate the following recovery plan and calculate these resistance values. The stuck vehicle is on soft gravel, has open differentials, and is getting cross-diagonal wheel spin on each axle due to uneven terrain. The vehicle can’t move forward or backward under its own power.

- Find the Mire Resistance. The stuck vehicle is not mired in mud, sand, or snow so you will not use a Mire Resistance value in this load assessment.

- Find the Damage Resistance. The stuck vehicle’s wheels will roll and not be dragged at any time when pulled by the winch. The vehicle is not damaged in any way. Therefore, you will not use a Damage Resistance value in this load assessment.

- Find Terrain Resistance. The stuck vehicle is on soft gravel, not solid rock. Therefore, you will use the Terrain Resistance value of 15% of the stuck vehicle’s GVWR, 5,700-pounds. Calculation: .15 x 5,700 = 855-pounds

- Find Slope Resistance. The stuck vehicle is on a steep hill with a slope of 25°. From Chart 2 you see that a 25° slope (rounded up to a 30° slope) adds a resistance of 50% of the stuck vehicle’s GVWR. Calculation: .50 x 5,700 = 2,850-pounds

- Safety Margin. Always add 25% of stuck vehicle’s GVWR to your total resistance calculations. Calculation: .25 x 5,700 = 1,425-pounds

- TOTAL Estimated Resistance. 855 Terrain Resistance + 2,850 Slope Resistance + 1,425 Safety Margin = 5,130 total pounds of estimated resistance.

- Find the Actual Pulling Capacity of the Winch on the Recovery Vehicle. To reach the stuck vehicle, you take off all but 3-layers of winch line from the winch drum. This means the 8,000-pound rated winch only has 80% of its original capacity – it is now capable of pulling approximately 6,400-pounds. Calculation: 80% of original capacity means it’s lost 20% of its total winching capacity. Therefore the calculation is as follows: 8,000 – (8,000 x .20) = 8,000 – 1,600 = 6,400-pounds.

• Recovery Plan. A single line pull may be able to pull the stuck vehicle up the hill; 5,130 total pounds of resistance being pulled by a winch capable of pulling 6,400-pounds. If the winch is electric, it may need rest periods to complete this difficult pull without over heating.

Scenario 3 Illustration

Scenario Four

After using the STOPA Checklist, you formulate the following recovery plan and calculate these resistance values. Unlike Scenario Three, this vehicle is damaged and its wheels do not roll properly.

- Find the Mire Resistance. You will not use Mired Resistance since the vehicle is damaged.

- Find the Damage Resistance. The stuck vehicle’s wheels will not roll; it is damaged. Using Chart 1 you determine the Damage Resistance is 66% of the stuck vehicle’s GVWR. Calculation: .66 x 5,700 = 3,762-pounds

- Find Terrain Resistance. You will not use Terrain Resistance since the vehicle is damaged.

- Find Slope Resistance. The stuck vehicle is on a steep hill with a slope of 25°. From Chart 2 you see that a 25° slope (rounded up to a 30° slope) adds a resistance of 50% of the stuck vehicle’s GVWR. Calculation: .50 x 5,700 = 2,850-pounds

- Safety Margin. Always add 25% of stuck vehicle’s GVWR to your total resistance calculations. Calculation: .25 x 5,700 = 1,425-pounds

- TOTAL Estimated Resistance. 3,762 Damage Resistance + 2,850 Slope Resistance + 1,425 Safety Margin = 8,037 total pounds of estimated resistance.

- Find the Actual Pulling Capacity of the Winch on the Recovery Vehicle. When rigging this recovery, you take off all but 1-layer of winch line on recovery winch drum. This means the 8,000-pound rated winch can pull its actual rated capacity.

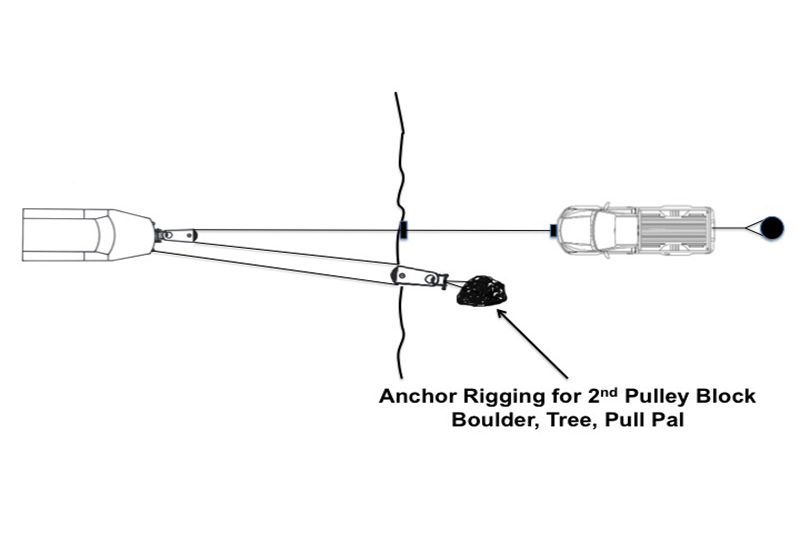

- Recovery Plan. The recovery plan includes a triple-line pull with two pulley blocks. One pulley block is attached to the stuck vehicle; the other is attached near the recovery vehicle, anchored at a boulder, tree, or Pull Pal land anchor. With the addition of two moving pulley blocks you effectively triple the efficiency of this winch (a moving pulley block reduces the work effort placed on the winch). The winch is now effectively capable of pulling approximately 24,000-pounds. (3 x 8,000 = 24,000). This rigging will easily help the winch pull the total estimated resistance of 8,037-pounds. The pull will be very slow, but the recovery vehicle will get the damaged vehicle up the hill ready for safe repair.

Scenario 4 Illustration – Side View

Scenario 4 Illustration – Top View

* OutdoorX4 Magazine – Promoting responsible 4×4 adventure travel and outdoor recreation