WARN Industries

Occasionally I go to lunch with a few of my hard working neighbors. On this day, I told them I couldn’t stay long since I was leaving tomorrow for a long road trip and needed to pack. Most of my local friends aren’t off-roaders, and most don’t even know what the term overlanding means. However, when asked where I has headed, I told them that I had the great privilege and honor of being invited to WARN Industries to tour the factory, meet with a few key executive personnel regarding some personal projects, and go wheeling in the snow around Mt. Hood with a group of WARN employees on Saturday. Without exception, every one of my friends said something like, “You mean WARN the winch company?” Even my mother-in-law knew the WARN name from her husband’s boasting and prideful install of original WARN hubs in the mid-1950’s on their trusty, old CJ2a Jeep. Now that is brand recognition.

Made in America With a Smile

WARN Winch

The WARN corporate offices, manufacturing factory, and distribution warehouse in northwestern Oregon is very impressive. Not simply from a square footage perspective (the factory is huge, approximately 400,000 square feet), but especially from the positive attitude of WARN’s employees. In nearly every job category, I noted an upbeat work ethic. With very few exceptions, employees were smiling while performing or talking about their job.

As I toured the factory, talking to their staff, I also noted that a large majority of WARN employees had worked for the company for over a decade. After catching on to this phenomenon, I began to randomly ask employees, “How long have you worked here?” Most of the executives, designers, customer service agents, laser cutters, CNC machine operators, welders, grinders, assemblers, and the like all responded in kind. “Oh, I’ve been here 32 years.” The next employee replied, “I’ve been here 25 years.” A similar interchange with the WARN staff continued throughout my tour. This level of employee loyalty and longevity is very special within a company, and from my experience, not often found. No doubt, this level of employee longevity and loyalty exists because the employees at WARN like working for the company, and because the leadership at WARN obviously makes employee-centric decisions. As anyone can tell you that have worked for a large company, a positive work atmosphere, and employee pride translate into the development, manufacturing, and assembly of quality products. It may sound sappy, but after meeting many WARN employees and watching the care they take to make and assemble fine off-roading products, I now smile and think of these folks every time I use my Zeon Platinum winch.

Besides the overwhelming positive attitude of WARN’s employees, it’s also nice to see vigorous manufacturing right here in the good ol’ USA. “Made in America” is not a catch phrase at WARN. Buy a bumper, winch, body armor, or 4WD hubs at WARN and by golly, it’s computer-aided designed, prototyped, tested, engineered, forged, extruded, cut, grinded, welded, machined, quality controlled, and assembled in Oregon. I like American engineering, ingenuity, pride, quality, and strength of build. You can get cheaper off-road products made oversees, but when I’m off-road, off-grid, and off-line exploring a remote backcountry venue, I want the finest equipment I can get my hands on. I know my WARN equipment can endure the hell I put it through. On occasion when I get stuck, I call on my WARN equipment to help return me safe and sound to my own special heaven – to my home or campsite.

The WARN factory and extended campus is impressive in size and manufacturing ability. Spread between two giant facilities, both buildings are in northwestern Oregon. (Aerial photos courtesy of WARN Industries)

Founded in 1948 by Arthur Warn, WARN Industries began producing locking hubs for surplus World War II Jeeps, converting them into useful, on-road vehicles for civilian work and play. As a testament to its founder, in the lobby stands “Big Red,” a 1948 CJ2a outfitted with Warn’s hubs and the company’s Belleview winch – a precursor to the renowned M8274 winch that is still made to this day.

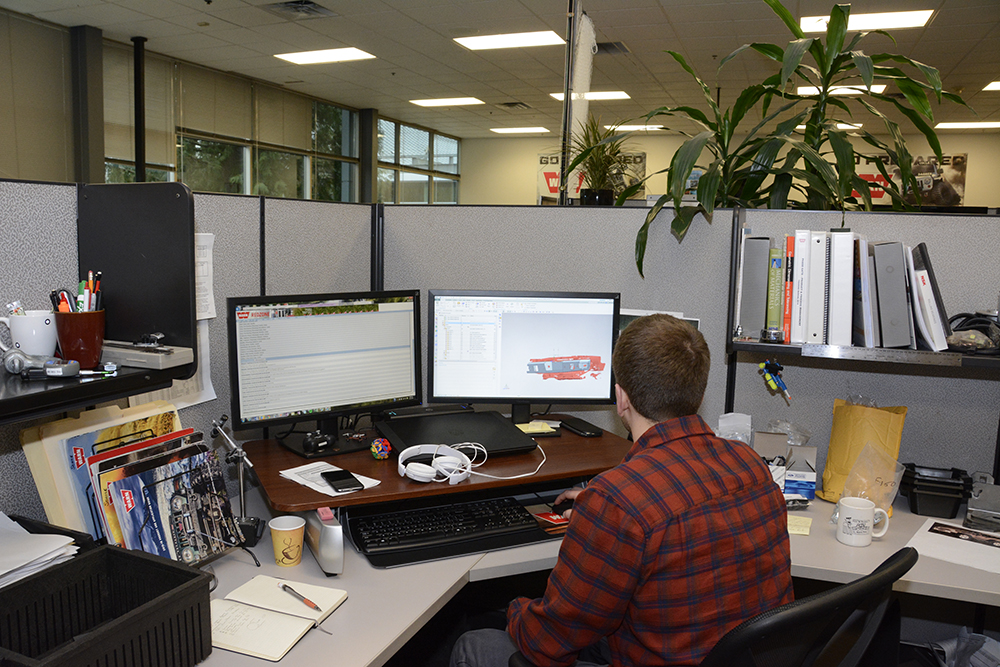

WARN’s American ingenuity, pride, and original parts design begins with its engineers using modern CAD (computer aided design) techniques.

From design to parts production, WARN’s equipment manufacturing begins with milling, forging, cutting, and casting most parts in-house.

Besides winches, WARN is also famous for it’s tough aftermarket bumpers for various vehicle makes and models. Bumper manufacturing begins with computerized laser cutting of thick steel plates.

Some pieces/parts can be welded robotically, but WARN doesn’t sidestep quality – they also use human craftsmanship and attention to detail through hand welding.

Your next winch drum could be in this photo.

WARN employees believe in what they do and take pride in making some of off-roading’s best aftermarket equipment.

The winch parts shown here will soon be assembled into a modern version of the venerable WARN M8274. The 8274 is WARN’s best known and most recognized winch. This winch is essentially unchanged since its first release in 1974.

WARN’s newest line of winches, Zeon’s progressing through complex assembly.

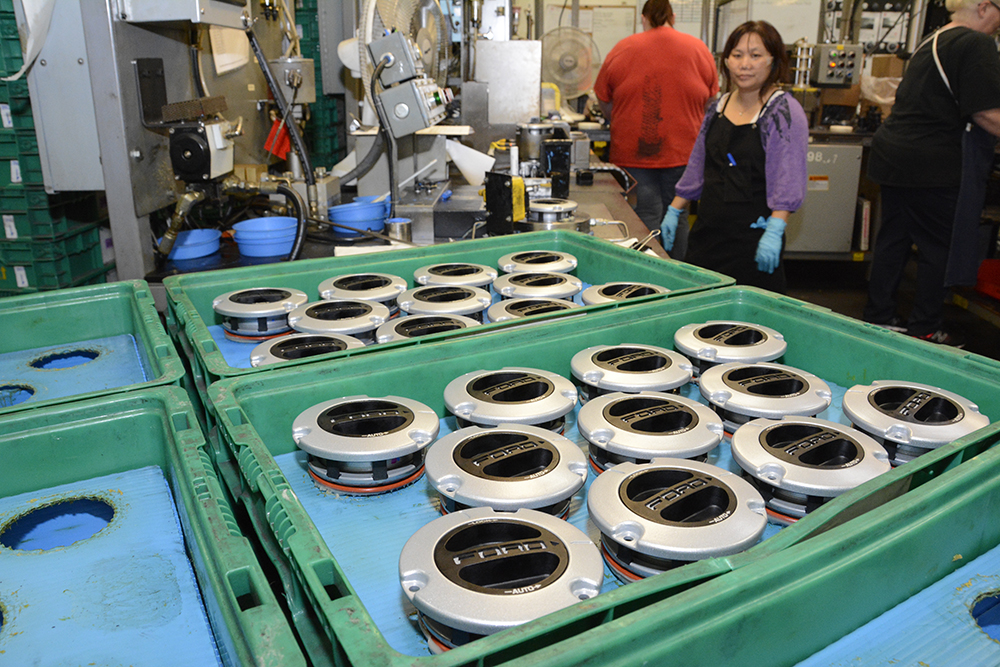

WARN makes a multitude of automobile parts under contract from several manufacturers. Here you see wheel hubs being assembled for one model of Ford’s 4WD truck line. When you purchase a Ford F-Series truck, you get well tested WARN hubs.

WARN equipment ready to ship to distributors worldwide.

Purchase WARN equipment and you get a whole team of customer service technicians and support personnel. Have a question about your WARN equipment, simply make the call.

WARN maintains a fleet of vehicles available to test prototype equipment, and to take to trade shows. Chad Schroll, WARN’s System Technician, looks after these vehicles, making sure they are “show ready.”

After touring the WARN factory, I was honored to be invited to wheel the snowy Mount Hood area with a large group of WARN employees. If you are wondering why WARN employees take pride in the products they build, you need look no further than the front bumper of their vehicles. Many WARN employees use the products they build.

* OutdoorX4 Magazine – Promoting responsible 4×4 adventure travel and outdoor recreation